What?

The best choice for cleaning storage tanks and transfer pipes is a CIP installation. These can be manually-operated or work fully automatically. The CIP installation controls the whole cleaning cycle, with for each phase the water and chemical consumption being controlled and variably adjusted. On the CIP return line there is also a conductivity meter, a flow switch and a temperature gauge to check that CIP has taken place as appropriate.

Advantages

Functional description and benefits:

The fluid bed batch-mixer is highly suitable for the continuous mixing of various types of bulk goods. Rotating shovels inside the horizontal mixer drum provide thorough and fast mixing with excellent mixing accuracies by mechanically creating a fluid bed.

Material enters the machine through the intake and is continuously blended and transported to the discharge.

The mixing paddle-geometry can be adjusted to the specific product characteristics at hand. This allows the blending and conveying of almost any powdery or granular material.

Various sizes and design features allow custom designed solutions for specific material characteristics.

Large cleanout doors guarantee quick cleaning and inspection.

SPECIAL ADVANTAGES

Customized design

Mixing accuracy of 1:100 000 and larger

Fast and intensive mixing

Jacketed housing for indirect heat exchange

Large doors for cleaning & inspection

Usable for dry powders, pastes, doughs & wet components

High-end surface finish

Sturdy design

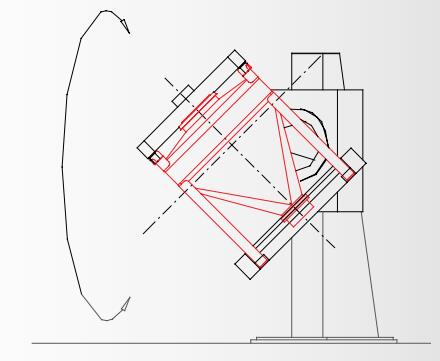

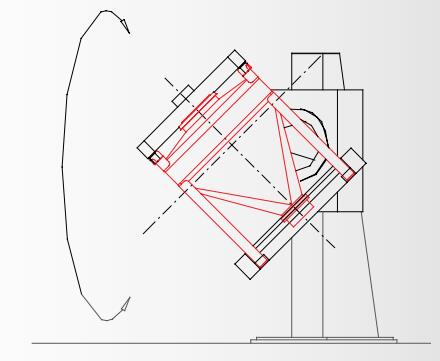

Functional description and benefits: The container blender is used for the mixing of component-batches inside the IBC. Containers are simply locked into the turning mechanism either manually or with a hydraulic clamping mechanism By turning and rotating the container asymmetrically the components are blended in a most gently way, hence any particle degradation can be avoided. An optionally integrated lifting function provides an easy integration into the entire flow of the production facility

Cross contaminations are eliminated by nature of container system

SPECIAL ADVANTAGES Elimination of cross-contamination Maximum on flexibility Minimized particle degradation Easy container cleaning Optional integrated lifting function Sturdy design Optional design for the foods-, animal feed-, chemical- & plastics-industries Optional dust explosion rated design (ATEX)

Hygienic, EHEDG compliant design, wherein dry and wet production sites are distinguished.

Dispersing and desagglomerating - food industry, dietetic food, nutritionial supplements and animal feed

Applications in the food industry:

SPECIAL ADVANTAGES

Customized design

Mixing precision of min. 1:100.000 and higher for variable batches, even as low as 10 percent of the capacity

Fast mixing process

Desinged to be tempered for für product heating & drying

Large doors for cleaning & inspection

Automatic cleaning in place (CIP) and disinfection are pos

Functional description and benefits:

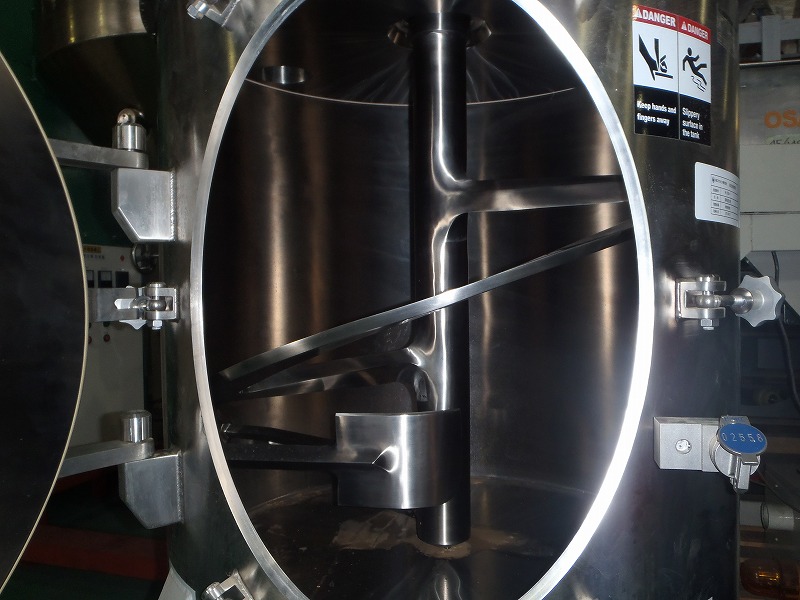

Vertical ribbon blenders obtain a very high degree of mixing quality within the shortest time. Sophisticated mixing operations can be carried out regarding products with many different densities, granulation and consistency in larger production areas.

The material to be mixed quickly enters the conical or cylindrical mixing space through a correspondingly large inlet and is simultaneously distributed by the mixing tools. The mixing spiral, held by strong, specially designed support and distribution arms and linked to the centrally arranged drive shaft, transports the content from the core to the outside and upwards along the wall. The product being mixed glides downwards in the middle and is horizontally mixed by the distribution and mixing arms during its progress to the bottom. The complete content is kept in constant motion in alternating directions, there are no dead zones. Even with batches as low as approx. 10 percent of the capacity, the optimum mixing quality is achieved.

With variable speeds adapted to the mixing product, an extremely gentle mixing or addition of coarse-grained materials is possible, likewise an extremely intensive dispersion of fine powders, paints / varnishes or liquid materials is achieved through high speeds.

Parts coming into contact with the product have smooth surfaces without joints. Nozzles can alternatively be equipped with aseptic flanges.

Corners are implemented as radii with R > 8 mm.

we also supplies CIP stations for automatic wet cleaning

A large inspection door facilitates not only comfortable cleaning by hand, but also any necessary inspections. Automatic cleaning in place (CIP) and disinfection are possible.

Clogging by highly adhesive products is counteracted with a nonstick lining. Installed in the cover next to the inlet are apertures for venting and non return values.

The outlet gates and flaps completely cover the base plate, so no dead zones.

Copyright © 2018 广州海特机电科技有限公司 All Rights Reserved. 网站建设:品拓互联